Gasketed Plate Heat Exchangers

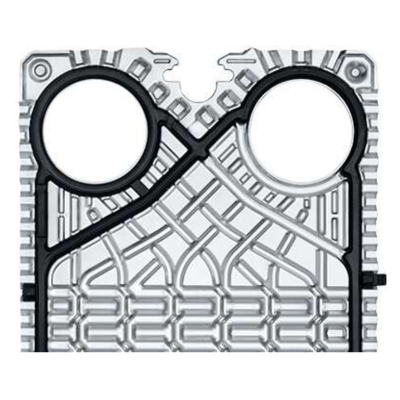

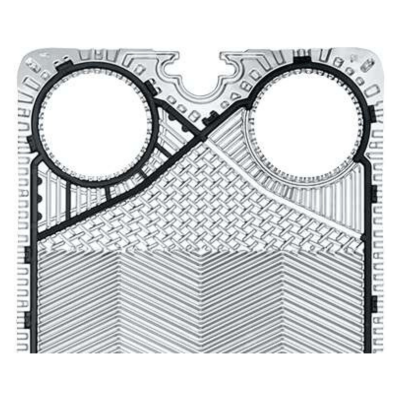

A Gasketed Plate Heat Exchanger (GPHE) is a type of heat exchanger that uses metal plates with gaskets to transfer heat between two fluids. They are known for their efficiency, compactness, and flexibility.

Fluid Dynamics is the Australian and New Zealand representative for Kelvion, a major international OEM of gasketed plate heat exchangers and is able to supply and expertly service complete gasketed plate heat exchangers, plate packs, plates and gaskets to suit all major OEMs.

Fluid Dynamics also has its own well-priced FluidEX® range of OEM-quality frames, plates and gaskets.

All of this is backed by our:

- decades of experience in the industry

- full design capabilities

- professional through-life Australia-wide support & service

- rigorous quality control and

- exceptional customer service

Types of GPHEs:

There are different types of GPHEs available, including:

Single-Pass: Fluids flow in one direction through the heat exchanger.

Multi-Pass: Fluids flow in multiple passes through the heat exchanger, increasing the heat transfer efficiency.

Free Flow: Designed for fluids with high viscosity or suspended solids.

Wide Gap: Used for fluids with large particles or fibers...

The Kelvion product series is detailed below.

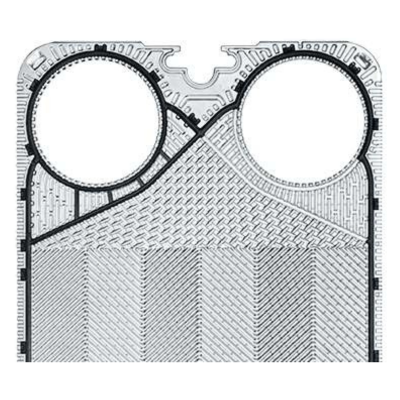

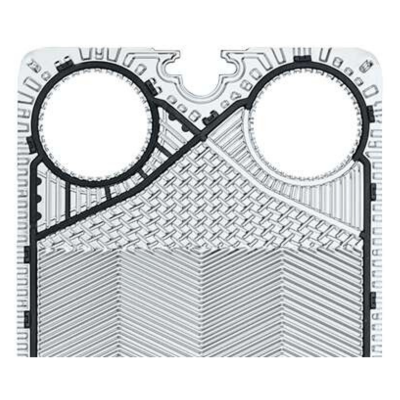

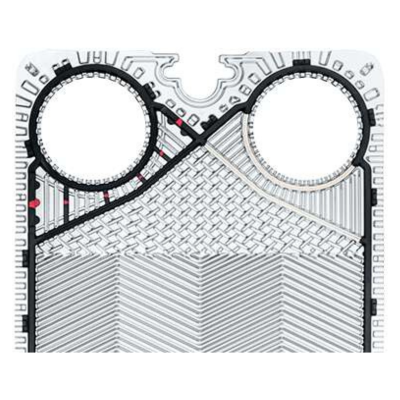

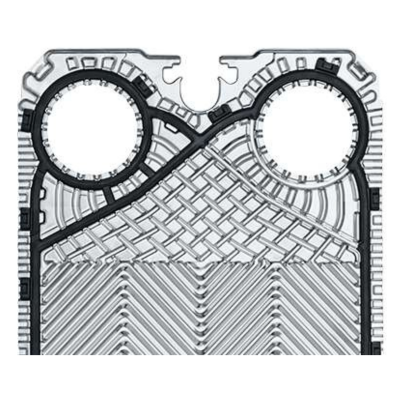

HPL

NT

NX

LWC

NP

NL

NW

NF

ND