Feedwater Heaters

Cost Effective & Environmentally Friendly Solutions

What is a Feedwater Heater?

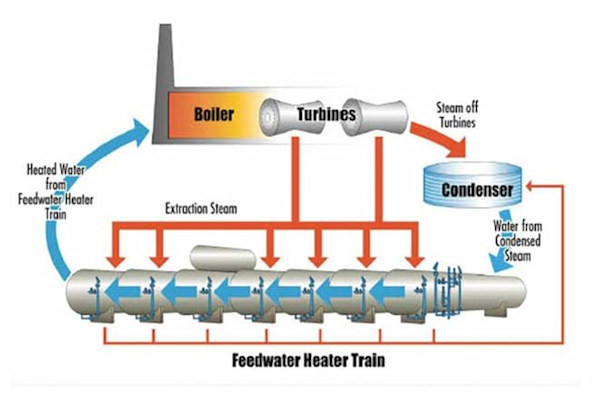

Feedwater Heaters are heat exchangers designed to preheat boiler feedwater by means of condensing the steam extracted from a steam turbine.

The tube-side fluid (condensate/water) remains enclosed in the tubes and does not mix with the shell side fluid (steam). Heat transfer within the vessel occurs by means of both convection and conduction rather than by combustion alone.

Unlike a surface condenser, the flow rate of steam into a Feedwater Heater is not limited by the amount of available steam.

The shell-side operating pressure in a Feedwater Heater is determined by the pressure of the steam, rather than by the amount of heat transfer surface.

Three types of Feedwater Heaters

- Low Pressure Heater (LP):

A Feedwater Heater located, with regard to feedwater flow, between the condensate pump and either the boiler feed pump or, if present, an intermediate pressure (booster) pump. It normally extracts steam from the low-pressure turbine. - High Pressure Heater (HP):

A Feedwater Heater located downstream of the boiler feed pump. Typically, the tube-side design pressure is at least 100 Bar, and the steam source is the high-pressure turbine. - Intermediate Pressure Heater (IP):

A Feedwater Heater usually located tube-side between the booster pump and the boiler feed pump. The typical tubeside pressure is between 65 and 100 Bar and steam is extracted from an intermediate pressure turbine.

Feedwater Heater design

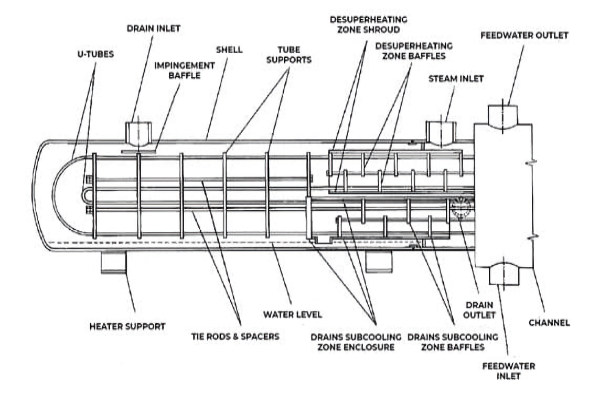

Most Feedwater Heaters are a shell-and-tube design in which a bundle of tubes (tube stack) is contained within the outer shell.

U-tubes are the most common tube bundle configuration as they are relatively resistant to thermal expansion during operation. In most configurations, the feedwater flows inside the tubes (tube side) and the steam flows over the tubes (shell side).

The positioning of Feedwater Heaters is flexible and they can be installed vertically, either head down or head up, or horizontally. Generally, their orientation is dependent on the design and the space available at the operation site.

Why use a Feedwater Heater?

Feedwater heaters serve a number of purposes, all of which provide significant cost savings and environmental advantages:

- Reduce fuel required for combustion by increasing the initial water temperature to the boiler;

- Reduce heat losses in the condenser;

- Minimize thermal transients within the boiler;

- Lower emissions as fuel use is reduced due to improved heat rate.

- Improve overall efficiency of the plant;

- Reduce operating costs; and

- Ease thermal stress on the boiler.

Orientation

Horizontal:

Horizontally mounted Feedwater Heaters occupy more floor space. However, most Feedwater Heaters are configured in this position as it provides the greatest stability in regard to water level control and offers convenient access for tube bundle removal.

Vertical:

Vertically mounted Feedwater heaters conserve floor space but there is reduced control volume available for liquid level fluctuation.

- Vertical – Channel Down: Disassembly is by shell removal. Installation and removal is likely to be more difficult than that for horizontally installed Feedwater Heaters

- Vertical – Channel Up: Least frequently used orientation. Disassembly is by bundle removal. If a subcooling zone is present, the zone must extend the full length of the bundle as the water must enter at the bottom end and exit at the top end of the Feedwater Heater.

Zones are separate areas within the shell of the Feedwater Heater:

- Condensing Zone:

All Feedwater Heaters have this zone and all of the steam is condensed in this area. Remaining, non-condensable gases must be removed externally downstream. The majority of the heat energy is added in this zone. - Subcooling Zone: (Optional)

The condensed steam enters this zone at its saturation temperature and is cooled by convective heat transfer from the incoming feedwater. - Desuperheating Zone: (Optional)

The incoming steam enters this zone giving up most of its heat to the feedwater exiting from the heater.

Feedwater Heater Engineering

Engineering a Feedwater Heater can be performed by thermal design and requires the following data be specified:

- Feed water inlet temperature

- Feed water inlet pressure

- Feed water mass flow

- Required outlet feed water temperature

- Bled steam inlet temperature

- Bled steam inlet pressure

- Flash steam mass flow

The design can also be re-engineered based on geometry:

- Internal dimensions of the tubes

- The tubes’ wall thickness

- Fouling factors

- The number of tubes and their length

- Baffle number and size

- Inlet and outlet nozzle inner diameters

- Shell inner diameter

Space constraints, materials and coating specifications are further factors to be taken into account in successfully designing and engineering Feedwater Heaters.