Scraped Surface Heat Exchangers

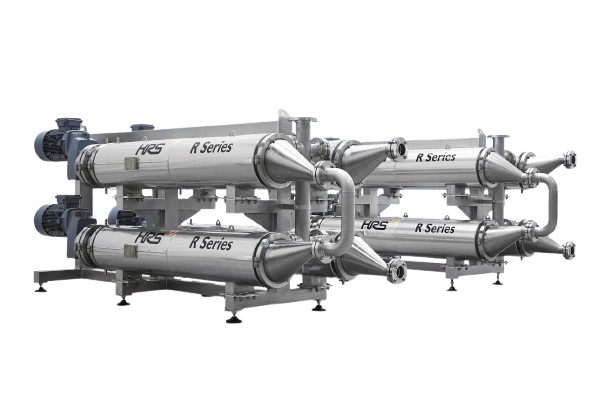

Fluid Dynamics, with its distinctive business approach, proudly offers a comprehensive collection of top-tier HRS Scraped Surface Heat Exchangers

Our engineers can tailor solutions specifically for you and combine exceptional quality with competitive pricing, all complemented by Fluid Dynamics’ unparalleled service.

ABOUT

Fluid Dynamics is the exclusive partner of HRS for Oceania and can supply HRS Scraped Surface Heat Exchangers which are expertly designed for the continuous processing of even the most viscous and complex products.

HRS Scaped Surface Heat Exchangers will elevate your production flexibility while maximizing thermal efficiency, yield, and quality, driving increased profitability. This enhanced performance stems from a fundamental principle: providing expansive heat transfer surfaces in a compact space to effectively heat or cool products in motion.

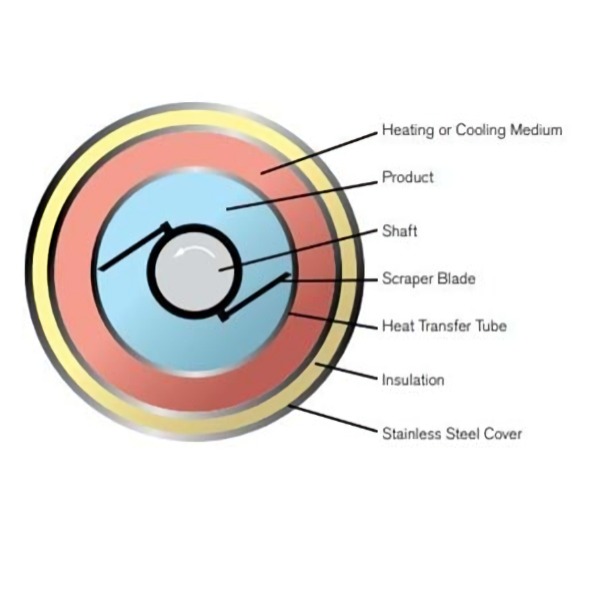

HRS Scraped Surface Heat Exchangers incorporate a motor driven mutator shaft which rotates within a tube.

The product passes through an annulus formed by the shaft and heat transfer tube while the heating or cooling medium flows in a jacket.

The unit is insulated to minimize energy loss and protect personnel and a stainless-steel cover protects the insulation.

Rotating scrapers firmly but gently remove fouling material from the tube’s inner wall during the process, preserving the quality of shear-sensitive products while providing high efficiency, a larger flow area and reduced pressure drop.

Each unit is individually engineered to handle all types of media – viscous, heat sensitive, crystallizing or sticky products and sensitive particulate matter.